I'm auditioning yet another CAM package, and I believe this one is going to be the keeper. not only is it able to do all I've asked of it in the basic entry level package, but it's currently on sale for $600 (vs. the reg price of $995) I have a 30-day temp license that allows me to generate the tool paths and also post the gcode, so I should have an opportunity to cut pink foam test articles in the very near future. if these are good ... I get to cut wood!

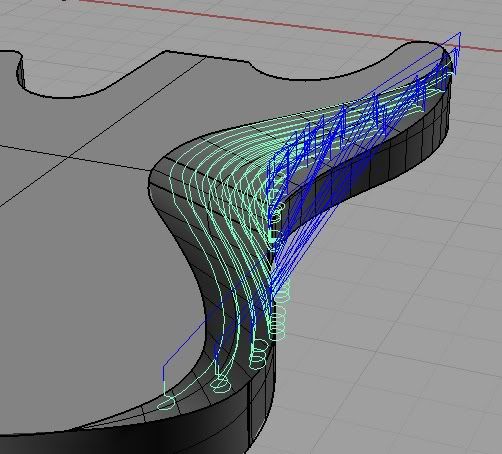

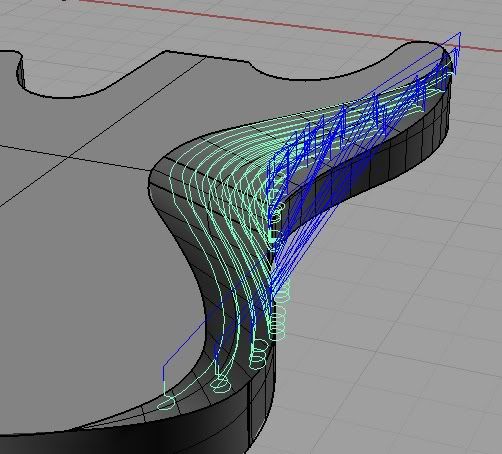

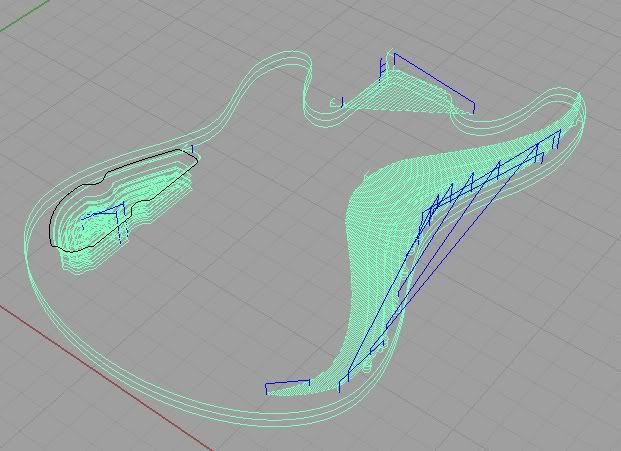

here's an image of the roughing passes for the rear gut-cut

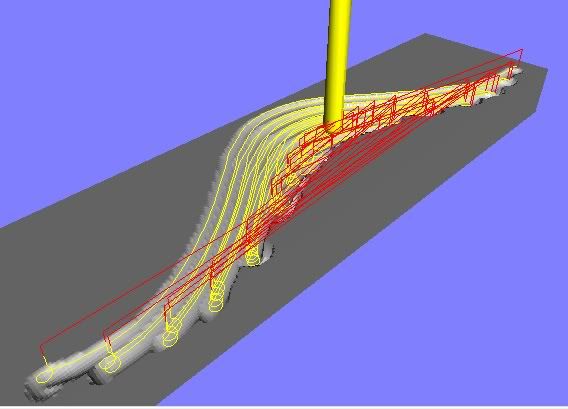

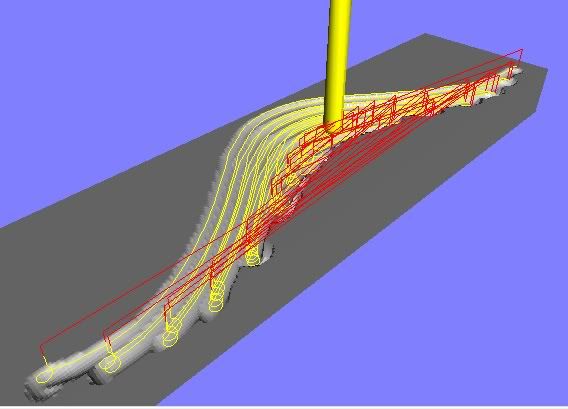

and then an image of the visual replay of the cutting code to verify that I've programmed to tool paths like I wanted. I've discovered this is a powerful tool for finding that you've cut the wrong part of the body and left behind the part you wanted to cut

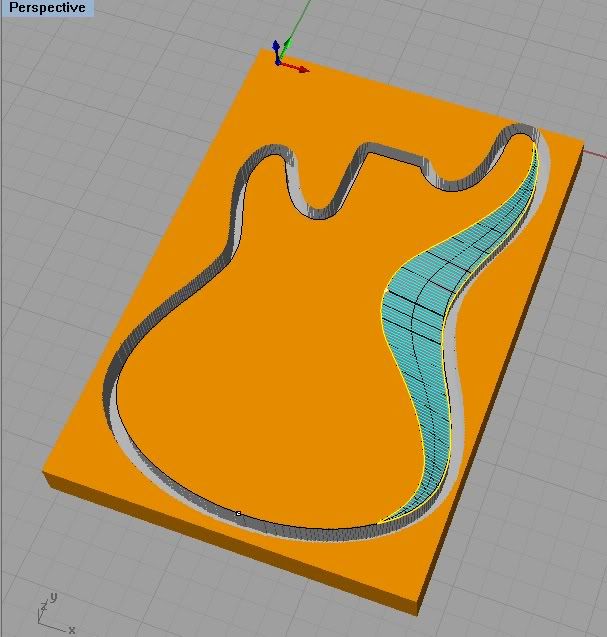

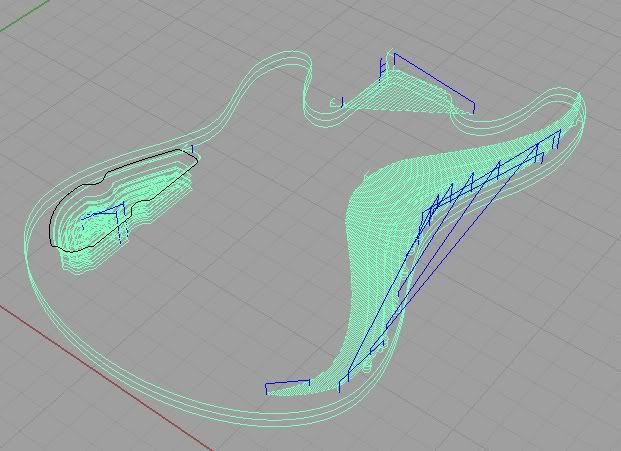

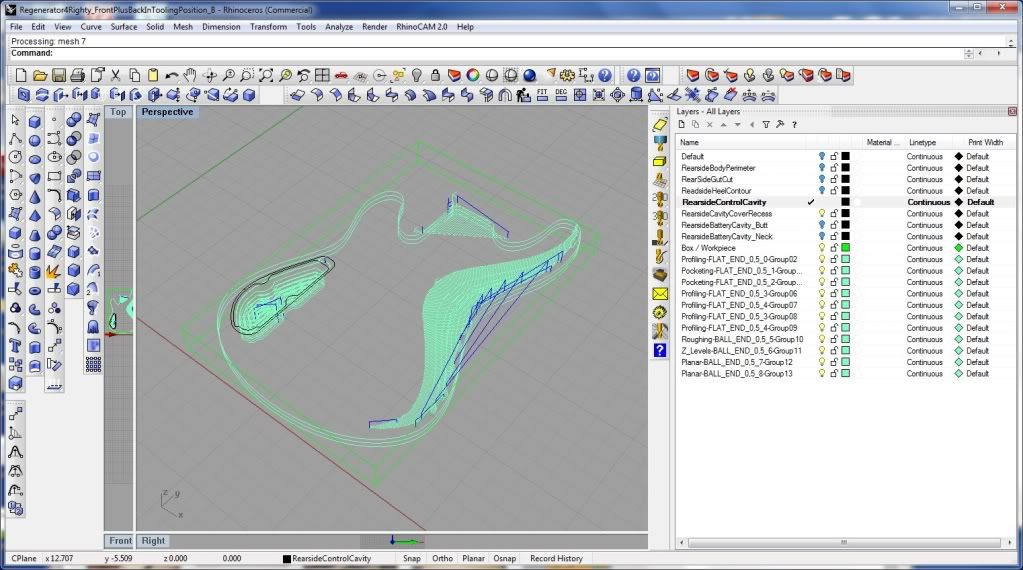

all of these pale green lines are centerlines of the cutting tool paths for the body outline, the control cavity, the control cavity cover recessed face, the heel contour, and the gut-cut. total estimated cutting time is under an hour, and I need to perform one cutter change (flat bottom to rounded bit) mid-way thru the cutting of this side. we'll see how that compares with reality once my machine controller code accounts for the feedrate changes coming in/out of sharp corners

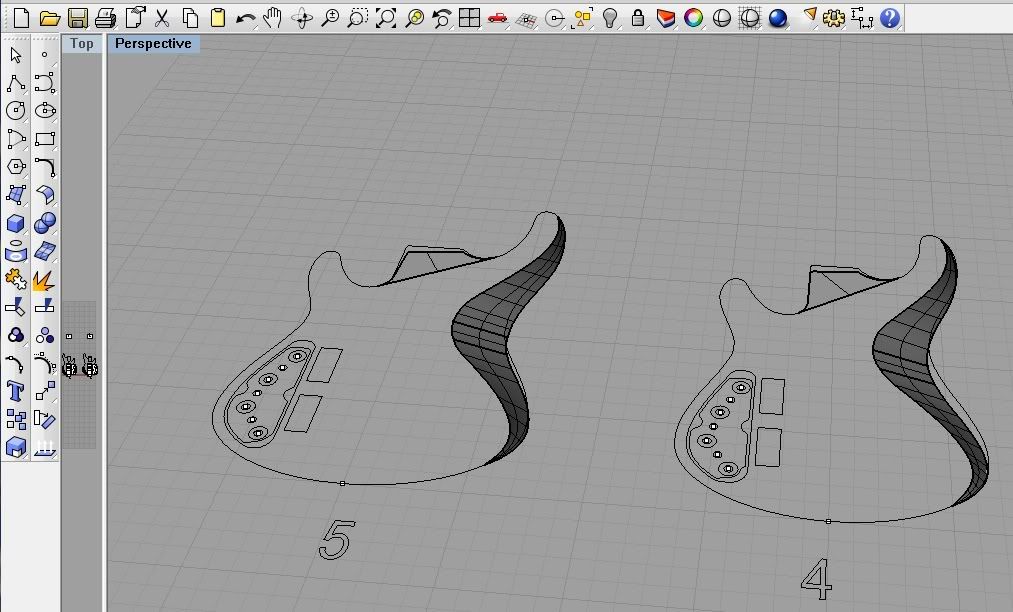

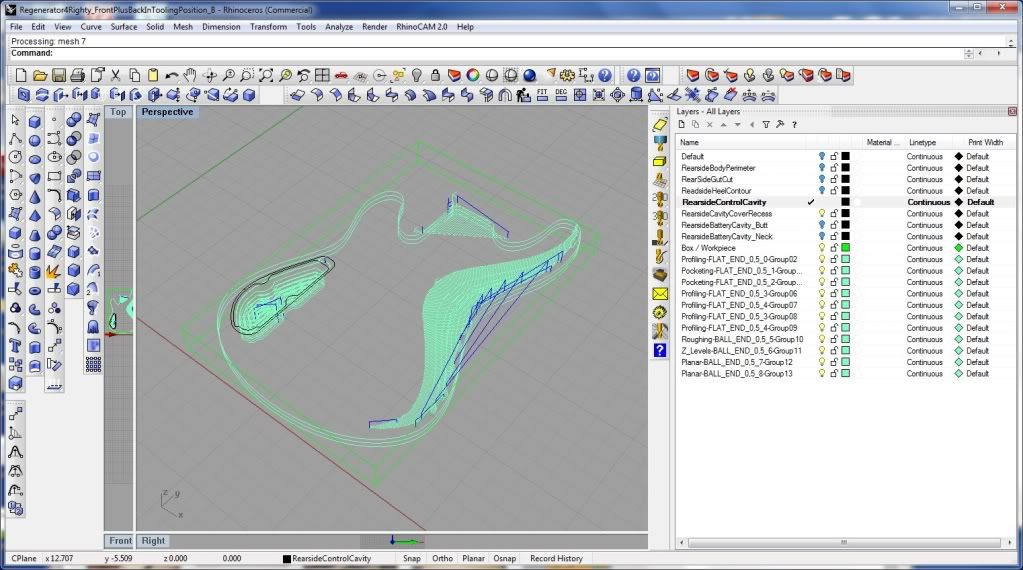

and just in case you wanted to see what I'm working with for a session display, here's my RhinoCAD session with the madCAM plug-in loaded and the rear side tool paths displayed

most of what I now know was learned purely by intuitive hacking - a reflective testament on how nice of a job the development team at Rhino and madCAM have done to make their tools powerful and user friendly. I would have loved to have done all this with the software I sell, but the company wasn't open to giving me an employee discount ... and I don't have a spare (

undisclosed really big amount) sitting around looking for a place to be spent

all the best,

R